Foldable cardboard gift box are very popular type of box. This type of box is not only flexible in design but also easy to carry and assemble. Especially it saves a lot of volume in store and transportation.

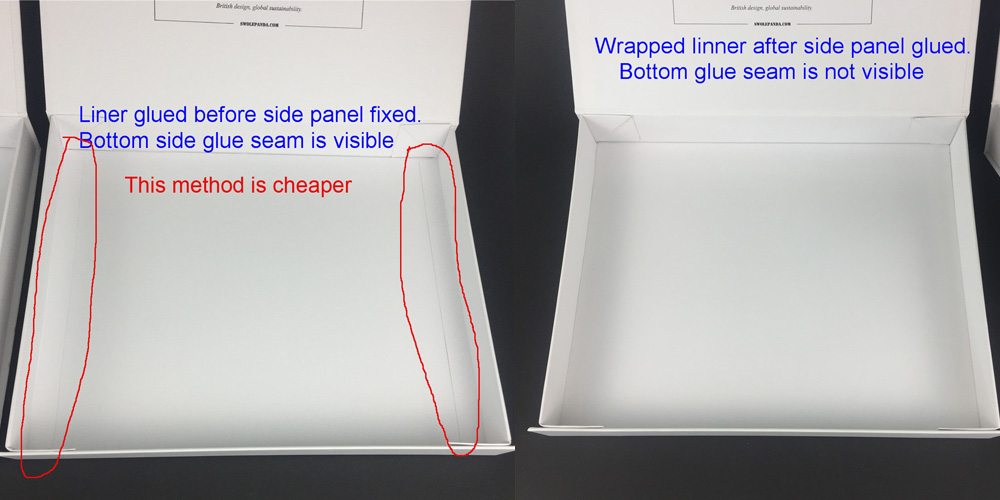

A traditional way of assemble a magnetic foldable box is to glue side-panel before applying jacket liner. After that we need to apply the liner manually which make production line a little bit awkward. However this is only necessary when the inside bottom have special graphic to display. We can enhance the efficiency and cut the cost by improve this procedure if there is no special graphic in the inside.

As you can check, our automatic machine can wrapped the jacket cover and liner perfectly and automatically. So without disturbing jacket wrapping, we glue the side panel to a double-sided pre-wrapped jacket. What we need to focus on is speeding up manual gluing side panels to jacket. When we get a foldable cardboard box inquiry, we will offer prices for this cost effective packaging solution. You can see the slightly difference between above two photos.

Our workers are well trained in this assemble procedures. It is really thrilling to see our guys quickly assemble side panels for each luxury foldable cardboard box. We really enjoy our daily magic show in our workshop.